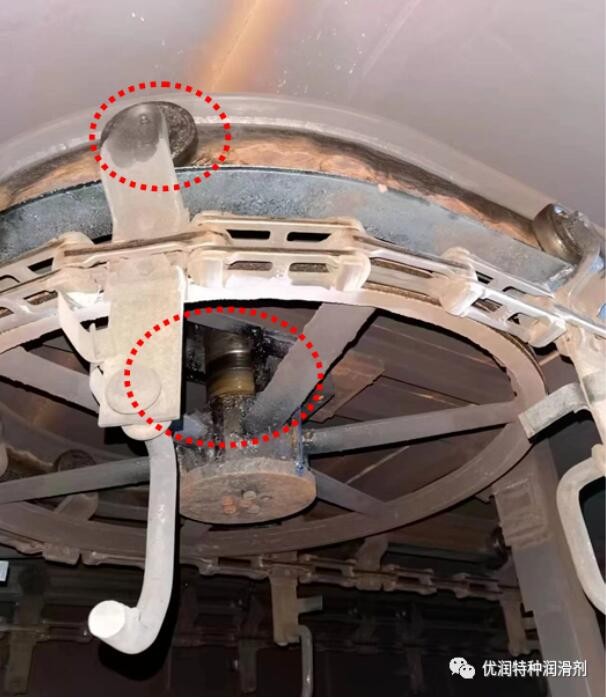

Lubrication test of wheel steering bracket bearing in rail vehicle under low temperature in winter

Read More

U.LUBE® is committed to the design of efficient lubricants to professionally improve efficiency,Over 30 years of experience in lubrication services and efficient lubrication solution design.

Get StartedOver 30 years of experience in lubrication services and efficient lubrication solution design.

We provide advice and strict follow-up services for initial priming lubrication of new gears, break-in lubrication for trial operation, operational lubrication for normal operation and repair of damaged gears in order to achieve good lubrication of open gears.

U.LUBE®, dedicated to efficient lubricant design and professional efficiency enhancement, provides tailor-made lubricating materials and field services for cement industry equipment.

U.LUBE®, dedicated to efficient lubricant design and professional efficiency enhancement, provides tailor-made lubricating materials and on-site services for steel and metallurgical equipment.

U.LUBE®, dedicated to efficient lubricant design and professional efficiency enhancement, provides tailor-made lubricating materials and field services for thermal power industry equipment.

U.LUBE®, based on international advanced design ideas and rich practical experience in the field, is a lubrication product developed and produced for the special needs of users.

cement, mining, steel, electric power, chemical and paper industries, such as: rotary kilns, ball mills, tube mills, rod mills, dryers, granulators, drum pulverizers, etc. Suitable for automatic injection lubrication system.

more

cement, mining, steel, electric power, chemical and paper industries, such as: rotary kilns, ball mills, tube mills, rod mills, dryers, granulators, drum pulverizers, etc. Suitable for automatic injection lubrication system.

more

temperature working conditions, such as industrial transmission chains, low speed rolling bearings, chains, bushings, etc. Also suitable for lubrication between rotary kiln, wheel belt and pad.

more

equipment in cement, mining, steel, electric power, chemical and paper industries, such as: dryers, granulators, excavators, roller presses, crushers, etc.

more

ships, docks, platforms and other steel wire rope. Applicable working temperature range: -20~160℃

more

conditions, especially for lubrication of steel continuous casting machine bearings and similar working parts, including: high working temperature...

moreFrom the perspective of equipment lubrication for enterprises to optimize lubrication management, change the concept of lubrication, reduce production costs, improve the reliability of equipment operation, so that equipment can achieve the best condition, to provide enterprises with suitable lubricant recommendations

U.LUBE team has more than 30 years of professional lubrication service experience, efficient lubrication solution design

Investigate the lubrication condition of the equipment and the working condition of the site by using tools such as thermal imager, vibration meter, stroboscope, camera, etc.

According to the field research situation to write equipment lubrication improvement plan, in order to help enterprise customers to solve the problem, to protect the production line

Share knowledge and concepts of equipment lubrication management with customers through training sessions and seminars

Provide oil inspection for customers and issue inspection reports

U.LUBE team has more than 30 years of professional lubrication service experience, efficient lubrication solution design

U.LUBE team has more than 30 years of professional lubrication service experience, efficient lubrication solution design

U.LUBE team has more than 30 years of professional lubrication service experience, efficient lubrication solution design

U.LUBE team has more than 30 years of professional lubrication service experience, efficient lubrication solution design

U.LUBE® has more than 40 branches in China, its distribution channels and technical service engineers can quickly and easily provide products and on-site support service.

U.LUBE team conducts U.LUBE lubricant test for cement plant customer's roller press

U.LUBE team performs vibration testing for rotary kiln in cement plant

The U.LUBE team installed and commissioned an automatic lubrication system for the mill open gears.

The U.LUBE team uses thermal imaging and stroboscopy to inspect the mill equipment

U.LUBE team changed the metalworking fluid for the machine

U.LUBE team successfully installed open gear automatic lubrication system for thermal power plant mill

Customer praise for U.LUBE's professional lubrication service and excellent lubrication products.

The U.LUBE team shared stories of field service, professional lubrication experience and technology, and the application effect of U.LUBE products.

2023-03-28

2023-03-28 2023-03-22

2023-03-22 2023-03-15

2023-03-15