Mining CITIC semi-self-grinding open gear lubrication improvement solution: temperature decreased 5℃, lubricant dosage decreased

The semi-autogenous mill Φ5.5x2.4m of a mine is produced by CITIC Heavy Industries and was put into operation in 2013. The working conditions of the semi-autogenous mill are generally low speed/heavy load, often accompanied by impact load and dust, and the working conditions are relatively harsh and its lubricant requirements are relatively high. The original use of a brand of open gear lubricant, used automatic spraying system of five nozzles for spraying, lubrication effect is not good, the temperature is relatively high. In order to reduce cost and increase efficiency, enterprises need to further optimize the lubrication of semi-autogenous grinding and other equipment.

After U.LUBE team's on-site research and analysis, after a communication with the owner, we decided to improve the current situation of open gear lubrication, enhance equipment protection and reduce grease consumption solution, and suggested to use U.LUBE high performance open gear operating lubricant ET G-OG C-FLUID 00, which has good adhesion performance, extreme pressure anti-wear performance, impact load resistance, and has necessary performance to adapt to operating conditions and environmental needs, such as high temperature resistance, water erosion resistance, strong sealing, reduced dust influence, good spraying performance, good pumping performance.

After replacing the oil use, the overall lubrication of semi-self-grinding open gear is basically stable, and the overall oil film changes significantly compared to before replacing the oil, and the graphite lapping area decreases more significantly compared to before replacing the oil (at this time the tooth surface temperature difference decreases by about 2℃).

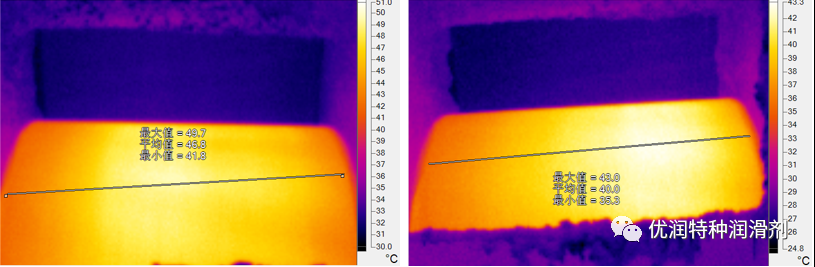

Tooth surface temperature before oil change (thermal imaging)

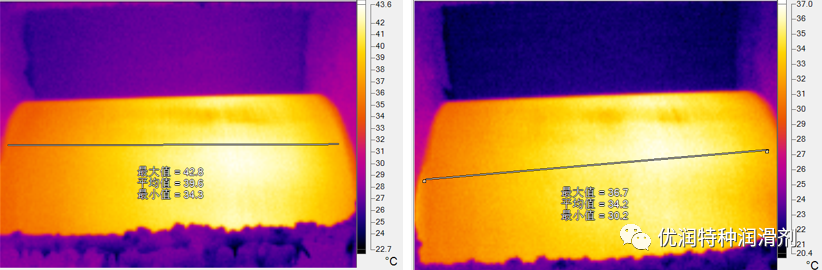

Tooth surface temperature after oil change (thermal imaging), temperature drop

From the infrared thermal imaging and heat accumulation, the tooth surface temperature distribution is uneven and the temperature difference is relatively large; the non-driven end near the middle of the gear has more heat accumulation and the corresponding temperature is higher, which indicates that there is a certain degree of load concentration in the large and small gears; the pinion temperature distribution does not change much after replacing with URS ET G-OG C-FLUID 00, the overall temperature drops about 5℃, the tooth surface temperature difference drops about 2℃, the ambient temperature drops 4-5℃ at this stage, the pinion tooth surface temperature difference and the average temperature have a tendency to decrease relative to the oil change before.

Before replacing the oil, the consumption of a brand of open gear lubricant is 50kg for about 35 days, and the spraying time of lubrication system is set to 20min spraying 15s; after replacing with U.LUBE open gear lubricant, the consumption of lubricant is 50kg for about 40 days, and the spraying interval of lubrication system is set to 30min spraying 5s, which has better pumping performance. Short-time spraying can also reach the required oil volume, according to the principle of small amount and multiple times, the actual use of the oil film on the tooth surface after replacing the lubricant is better than before, and can effectively reduce the temperature of the tooth surface and oil usage while meeting the normal lubrication of the equipment, and the comprehensive price is relatively high.

Lubrication of large gear tooth surface after oil replacement